You have seen the different types of air compressors that you should buy. Which one should I choose?Here are some valuable tips that you can use for choosing the best industrial air compressors in chinese compressor manufacturers:

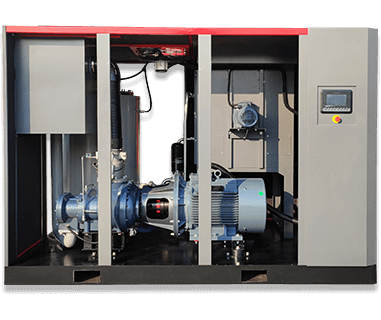

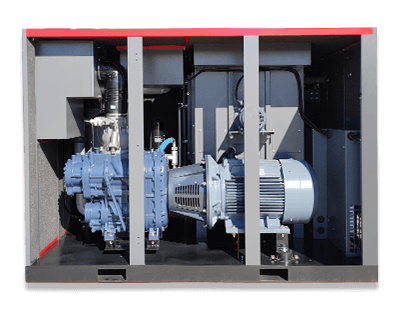

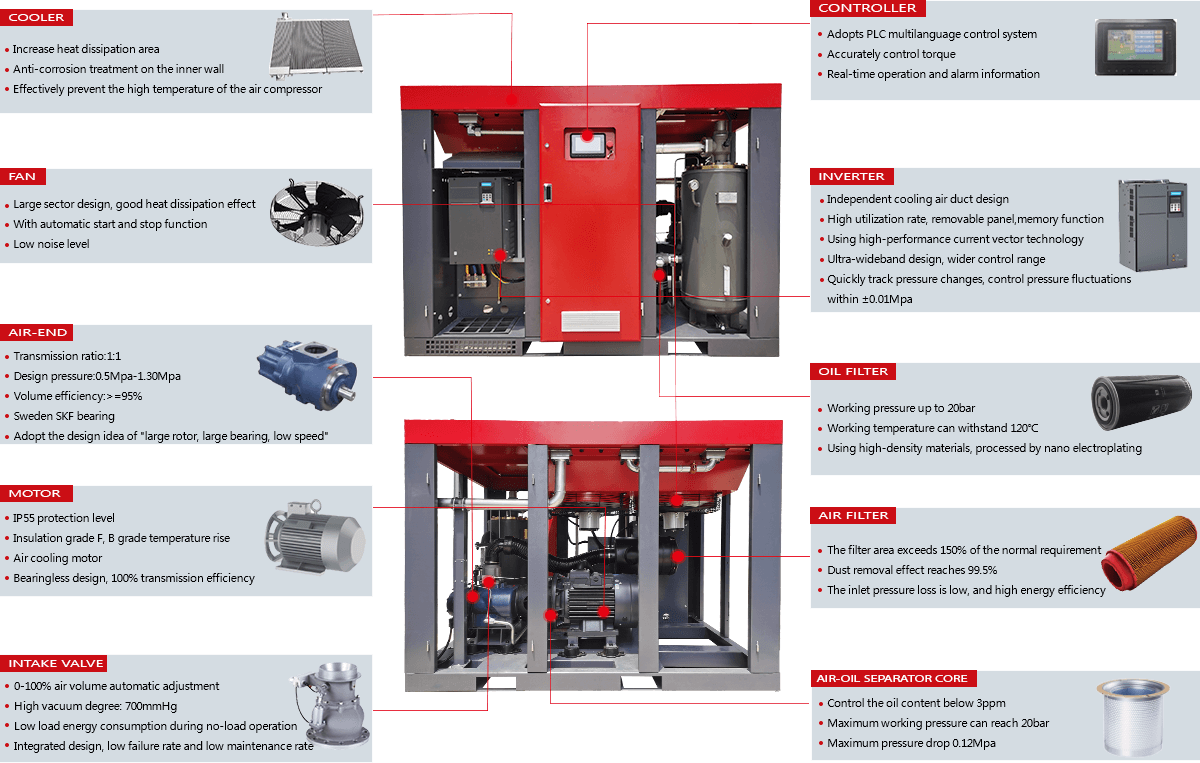

Analyze your industrial requirements:What kind of machines or applications will you be using on the air compressor? This is vital because industrial air compressors have different output performance.Ensure that the industrial compressor that you will choose matches your requirements.For example, if you have demanding equipment, then you will have to get high-pressure industrial air compressors.

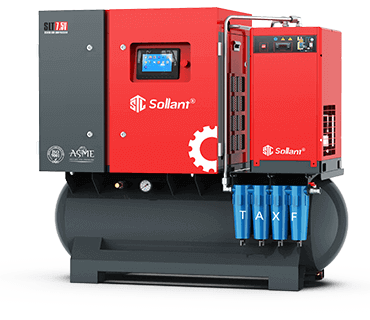

Size of the industrial air compressor:Be sure to get the right size of industrial air compressor. This is because smaller industrial air compressors are not efficient enough to deliver high pressure air.Nowadays, you can find a wide range of industrial air compressors in different sizes like small, medium and large.

Power consumption:Power consumption is one of the most important factors when choosing an industrial air compressor factory because. The power consumption will determine how much electricity your industrial compressor uses throughout its lifetime.Are you thinking of saving the electricity bills?You have to choose an industrial air compressor that consumes less power and has a long lifespan in order to save on energy costs.The good news is that in recent years, OEM compressor manufacturers have been striving to develop energy-efficient air compressors for sale.

Check the horsepower:It is important to check the horsepower of industrial air compressors because it will determine how much air your compressor can pump out of a tank.You can use your compressor to pump out different types of liquids such as water, oil and others.Most industrial air compressors have a horsepower ranging between 1.5 hp to 6.5 hp. Also this information is usually indicated by the air compressor manufacturing company.

Space:We always tend to assume that industrial air compressors are sizable. But, do you have adequate space in which the air compressor can fit? The size of an industrial air compressor is important because, if it is too small, you won't be able to use your compressor in a large area. On the other hand, if it is too big, you will need a bigger space for storing the air compressor.

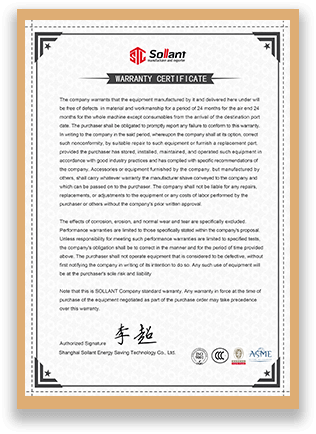

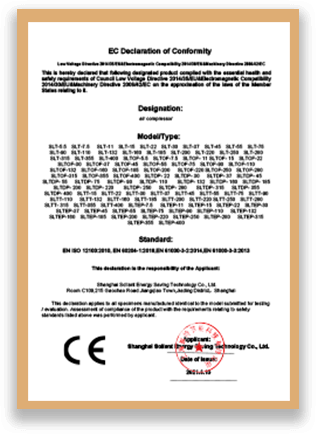

Industrial air compressor manufacturers: Where are you buying your industrial air compressor? Are you sure that the air compressor manufacturers will meet your needs?It is important to check the industrial air compressor suppliers because you can get a wide range of products from them.They have different pricing and different specifications which you can choose from.If it is a Chinese compressor, try to find out what the best air compressor vendors in China are.

Portability: Is your industrial air compressor portable? If not, it will be a problem for you to move the air compressor around. It is also important for you to consider the portability of an industrial air compressor because.If it is too heavy to carry around, you will be less likely to move it from one place to another. If a small size industrial air compressor can fit in your car's trunk or on your truck's trailer, that would be ideal for moving it around because, if it's too big, there won't be enough space for storing it.

I hope at this point you are fully equipped to buy industrial air compressors in China. Compression machine manufacturers in China are well-equipped to deliver a reliable air compressor for your application. Simply contact them and place your order from the largest air compressor manufacturers.

.jpg)

.jpg)

.jpg)